People may often think that piping and tubing are the same thing, but they are two very different items regarding steel manufacturing. Steel Tube and Pipe Difference - Steel pipe is always round, whereas steel tubing can be produced in round, square and rectangular shapes. This article will define what is considered piping and tubing, and it will also describe the main differences between the two.

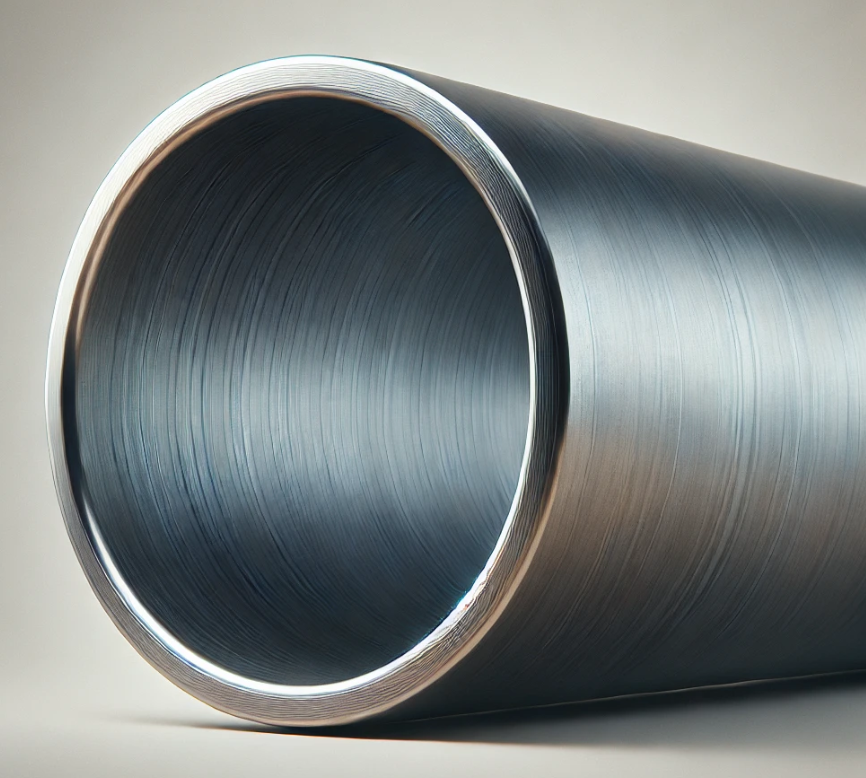

Steel Pipe

As stated above, steel pipes are exclusively round, and they are used to transport different gases and fluids across a variety of industries. Steel pipes play a crucial role in the metal industry due to their versatility, durability, and strength. They are widely used in various applications, including construction, manufacturing, and transportation. Steel pipes are commonly found in structural frameworks, water and gas transportation, oil pipelines, and mechanical systems. The manufacturing process, often involving welding or seamless production, allows for a range of sizes and thicknesses to suit specific needs. Their resistance to corrosion and high-pressure tolerance makes them ideal for demanding environments like oil refineries, chemical plants, and power generation facilities.

One of the most important characteristics of steel tube is the inside diameter (ID). This will determine the amount of liquid or gas that can flow through the pipe at a given time. Another important characteristic of steel pipes is the pipe schedule, or wall thickness. The two most common wall thicknesses are Schedule 40 and Schedule 80. Schedule 40 pipe has a thinner wall thickness than Schedule 80 pipe, so it is better for applications that require less PSI (pounds per square inch). The price of piping depends on the size of the pipe, but they are usually cheaper than tubing due to an easier production process.

In addition to their functional advantages, steel pipes contribute significantly to sustainability in the industry. Many steel pipes are made from recycled materials, and their long lifespan reduces the need for frequent replacements. This makes them both cost-effective and environmentally friendly. Technological advancements have further enhanced the properties of steel pipes, improving their efficiency and performance across industries. As a key component in infrastructure projects and industrial systems, steel pipes continue to be a vital material in the evolving landscape of modern engineering and manufacturing.

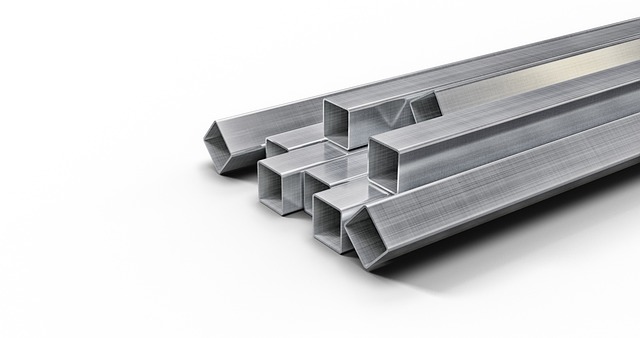

Steel Tube

Steel tubes are used in applications where durability and strength are important. They come in a variety of shapes including round, rectangular, and square, which is one of the distinctive differences between piping and tubing. Steel tubes are a fundamental component in the metal industry, valued for their strength, precision, and adaptability. Unlike steel pipes, which are generally used for the transportation of fluids and gases, steel tubes are often found in structural applications such as construction, machinery, and automotive manufacturing. Their smaller diameter and often more precise dimensions make them ideal for applications requiring tight tolerances and higher strength-to-weight ratios. Steel tubes are commonly used in building frameworks, scaffolding, bicycle frames, and furniture manufacturing, where they provide both support and aesthetic appeal.

Steel tubes can be produced in one of two methods.

- Electric Resistant Welded (ERW) tubes are produced by forming a steel coil into the specified shape and then welding the two ends at the seam.

- Seamless tubes are manufactured by taking a round piece of steel and then stretching and piercing the middle until it takes the form of a tube. Steel tubes are usually classified by the outside diameter and dimensions, but another important characteristic to consider is the wall thickness.

Some of the more notable applications of steel tube include uses in the construction and engineering fields, as well as in automobile manufacturing. Steel tubing production requires more energy, labor and material cost resulting in a higher overall price than most steel pipes. The versatility of steel tubes extends to their wide range of shapes, including round, square, and rectangular profiles, which are used depending on the specific application requirements. Technological advancements, such as seamless tube manufacturing processes, have improved the quality and performance of steel tubes, enhancing their durability and resistance to wear and pressure. Additionally, steel tubes are often galvanized or treated to resist corrosion, making them suitable for both indoor and outdoor applications. In the metal industry, steel tubes remain a critical material, offering an excellent balance of strength, lightweight characteristics, and precision for various industrial and consumer products.

Some of the more notable applications of steel tube include uses in the construction and engineering fields, as well as in automobile manufacturing. Steel tubing production requires more energy, labor and material cost resulting in a higher overall price than most steel pipes. The versatility of steel tubes extends to their wide range of shapes, including round, square, and rectangular profiles, which are used depending on the specific application requirements. Technological advancements, such as seamless tube manufacturing processes, have improved the quality and performance of steel tubes, enhancing their durability and resistance to wear and pressure. Additionally, steel tubes are often galvanized or treated to resist corrosion, making them suitable for both indoor and outdoor applications. In the metal industry, steel tubes remain a critical material, offering an excellent balance of strength, lightweight characteristics, and precision for various industrial and consumer products.

Steel Tube and Pipe Difference

Steel tubes and steel pipes, though often used interchangeably, serve distinct purposes in the metal industry due to differences in their design, applications, and manufacturing processes. The primary distinction lies in their intended function: steel pipes are typically used for transporting fluids and gases, while steel tubes are more often utilized in structural and mechanical applications. This difference influences the way they are measured—pipes are measured by their inner diameter (ID) to ensure a specific flow capacity, whereas tubes are measured by their outer diameter (OD) for precision in structural applications. Consequently, pipes prioritize the volume they can carry, while tubes focus on external dimensions for fitting into systems or providing structural support.

Another key difference between steel tubes and pipes is their shape and strength. Steel pipes are generally circular and designed for pressure handling, making them ideal for systems such as water, oil, or gas pipelines. In contrast, steel tubes come in various shapes—round, square, rectangular, or even oval—depending on the needs of the project. Tubes often have stricter tolerances and better consistency in their measurements, making them more suitable for uses where precision is critical, such as in automotive, aerospace, and construction industries. The varying shapes and higher strength-to-weight ratio of tubes make them ideal for structural applications like scaffolding, machine components, and even furniture.

The manufacturing process also differs significantly between pipes and tubes. Pipes are often manufactured through a welding process, although seamless pipes exist, primarily for higher-pressure applications. On the other hand, steel tubes can be produced either through welding or a seamless process, with seamless tubes offering superior strength and resistance to corrosion, particularly in high-pressure or high-stress environments. Tubes also undergo more rigorous testing and quality control to meet the precision and strength requirements of industrial applications. Ultimately, while both steel tubes and pipes are essential to various sectors, their distinct characteristics make them suitable for different roles in the metal industry.

Visit our products page to find out more about the steel tubing and pipe products we have to offer here at ECONSTEEL!