Abrasion-resistant (AR) steel is a type of high-carbon alloy steel. The alloys in it make it formable and weather resistant, and the amount of carbon in the steel can affect the hardness when heat treated. When reading these types of steel grades, such as AR400 and AR500, it is important to note that the number following the letters AR represents the hardness range of the steel.

AR steel is often used in applications where the material will experience failure via wear and tear or abrasions over time. Let's talk about the key differences of AR400 vs. AR500 steel, and how we can best employ them.

Measuring hardness of AR steel

As mentioned earlier, the number in the AR steel description represents the hardness range of the steel, a number that is based on the Brinell Scale. The Brinell Scale characterizes the hardness of steel through the scale of penetration of an indenter loaded on a material test piece. AR400 steel falls between 360 BHN and 440 BHN, whereas AR500 steel falls between 477 BHN and 550 BHN on the Brinell Scale. Though these two grades have similarities, the key difference between the two is a characteristic called impact resistance.

Impact resistance of AR400 vs. AR500 steel

Impact resistance describes the energy required to break a piece of test material into two pieces or more. AR400 steel is known to have a high impact resistance, so it is used in applications like in the bed of a dump truck. The bed of the dump truck will experience impacts when things are loaded in and out of the bed, so it is important you use a steel like AR400 that has a high impact resistance and will not shatter over time.

Comparatively, AR500 steel is known to have a high abrasion resistance. This results in AR500 steel being used for applications where the material will be exposed to wear and tear from materials rubbing against them rather than being dropped onto them such as in AR400 applications.

Choose the best material for the job

It is important to be aware of the physical and chemical properties of the materials you use, and it is equally important to know the difference between those properties amongst grades. This will ensure you select the best material for the given objective. Contact the knowledgeable team at ECONSTEEL for help selecting the best steel grade for your application.

AR400 vs AR500

Abrasion-resistant (AR) steel is widely used in industries requiring durable and tough materials. Two of the most common grades are AR400 and AR500 steel. While they share similarities, key differences impact their application and performance.

What is AR Steel?

AR steel is a high-carbon alloy steel designed for increased hardness and resistance to wear and abrasion. It is commonly used in mining, construction, and manufacturing where impact and friction wear down regular steel.

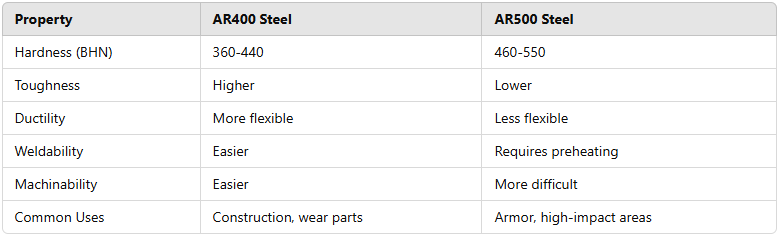

Key Differences Between AR400 and AR500

-

Hardness

-

AR400: Brinell Hardness Number (BHN) of 360-440

-

AR500: BHN of 460-550

-

AR500 is harder than AR400, making it more resistant to wear and impact damage.

-

-

Toughness & Ductility

-

AR400 is tougher and more flexible, making it suitable for applications requiring bending or forming.

-

AR500 is more brittle due to its increased hardness and is best for high-wear applications where flexibility is not a concern.

-

-

Common Applications

-

AR400: Dump truck liners, bulldozer blades, wear strips, and industrial hoppers.

-

AR500: Ballistic armor, shooting targets, mining equipment, and high-impact surfaces.

-

-

Weldability & Machinability

-

AR400: Easier to weld and machine due to its lower hardness.

-

AR500: More challenging to weld and machine; preheating is often required.

-

Comparison Chart

Which One Should You Choose?

-

For applications requiring impact resistance and some flexibility, AR400 is the better choice.

-

For extreme wear resistance and hardness, AR500 is ideal, particularly for ballistic protection and high-abrasion environments.

Both AR400 and AR500 steel offer excellent durability and resistance to wear, but their differences in hardness, toughness, and machinability dictate their best use cases. Choosing the right steel depends on the specific demands of your application.