When it comes to the world of metallurgy, few materials hold as much importance as steel. It's the backbone of our modern industrial society, used in everything from buildings to vehicles to cutlery. But have you ever wondered what gives steel its incredible range of properties and versatility? The answer lies in its carbon content. The relationship between carbon content in steel and steel properties is a fascinating one, and understanding it is crucial for designing materials with specific characteristics.

Carbon as a Metamorphosis Agent

Steel is primarily composed of iron (Fe), with a small percentage of carbon (typically less than 2.1%). The amount of carbon present in steel has a profound impact on its properties. In fact, it can change a piece of iron from a soft, malleable metal into a tough and durable alloy. As the carbon content in steel increases, steel undergoes a transformative process, transitioning from low carbon to high carbon steel.

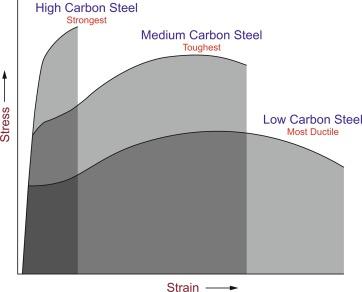

The carbon content in steel plays a critical role in determining its properties, such as hardness, strength, and ductility. Steel can be categorized based on its carbon content, transitioning from low carbon steel (mild steel) to high carbon steel. Low carbon steel, typically containing less than 0.3% carbon, is softer, more ductile, and easier to weld or form, making it ideal for construction materials and automotive parts. As carbon content increases, moving into medium carbon steel (0.3% to 0.6%), the steel gains higher strength and hardness but becomes less ductile. High carbon steel, with over 0.6% carbon, is extremely hard and strong, often used in cutting tools, springs, and high-strength wires, though it is more brittle and challenging to weld. This transition in carbon content allows manufacturers to select the right type of steel depending on the mechanical requirements of the application.

Low Carbon Steel

Low carbon steel, also known as mild steel, with a carbon content of up to 0.30%, is characterized by its ductility and malleability. This type of steel is easy to shape, weld, and form, making it suitable for applications like automotive bodies, construction materials, and structural components. It is highly versatile and can be easily welded, machined, or formed into various shapes, making it ideal for structural applications, automotive components, and general fabrication. Low carbon steel is relatively soft and tends to be less strong but highly workable. While it lacks the hardness and strength of higher carbon steels, its flexibility and lower cost make it a popular choice for projects where toughness and malleability are more important than extreme strength.

Medium Carbon Steel

Medium carbon steel, with carbon content ranging from 0.30% to 0.60%, strikes a balance between ductility and strength. It is stronger and harder than low carbon steel but retains enough ductility to be used in applications requiring moderate toughness. Medium carbon steel is often used in machinery components, automotive parts like axles and gears, and structural elements that need to withstand higher loads and wear. It's often used in applications like gears, axles, and machinery parts, where the need for both strength and formability is critical. While it is more difficult to weld and form than low carbon steel, medium carbon steel can undergo hardening heat treatments like quench and tempered to increase its hardness and wear resistance. This further enhances its mechanical properties, making it suitable for demanding applications.

High Carbon Steel

High carbon steel contains carbon in the range of 0.60% to 2.1% and is known for its exceptional hardness and strength, but at the cost of reduced ductility and toughness. Due to its high carbon content, this steel type is extremely wear-resistant and is often used in applications where durability and cutting ability are essential, such as in cutting tools, blades, springs, and high-strength wires. This steel type is commonly used in making cutting tools, such as knives and chisels. High carbon content in steel can hold a sharp edge and withstand significant wear and abrasion. While it offers superior hardness, high carbon steel can be brittle and difficult to weld or form without cracking. However, it tends to be less ductile and may require special heat treatment to achieve the desired properties. Heat treatments, such as tempering, are often applied to improve its toughness and reduce brittleness, making it a valuable material for high-performance applications.

Finding the Sweet Spot

The key to utilizing steel effectively lies in finding the right balance of carbon content. The steel industry employs precise control over carbon levels and the addition of other alloying elements to tailor steel to specific applications. This practice allows engineers and manufacturers to create materials that meet the exact requirements of a given project, be it a skyscraper's structural beams, an aircraft's landing gear, or a chef's favorite knife.

In conclusion, the carbon content in steel is the magic wand that metallurgists wield to shape and mold this remarkable material into countless forms, each with its unique set of properties. From the soft and workable low carbon steel to the hard and resilient high carbon steel, the world of steel is as diverse as the applications it serves. The next time you encounter steel in your daily life, remember the hidden influence of carbon and the incredible range of possibilities it unlocks.